Margins matter more than ever, in manufacturing.

Knowing exactly how many orders your team can fulfil in a day, a week or a month, ensures that your operations are always optimised – and profitable.

That’s where capacity planning comes in.

Capacity planning is an important lean manufacturing principle, enabling businesses to consistently meet customer demand, maximise team utilisation and reduce production costs.

In this post, we’ll explain:

- What is capacity planning?

- Lead, lag and match capacity planning

- Why capacity planning is important?

- Pros and cons of capacity planning

- How capacity planning works

- Advanced capacity planning with Wiise

- Capacity planning in practice

- Capacity planning with confidence

1. What is capacity planning?

Capacity planning is the practice of calculating how much you can deliver in a given timeframe, in order to meet customer demand. While it’s useful in most industries, capacity planning is particularly crucial in manufacturing, where under-utilised staff or machinery can have a direct impact on the bottom line.

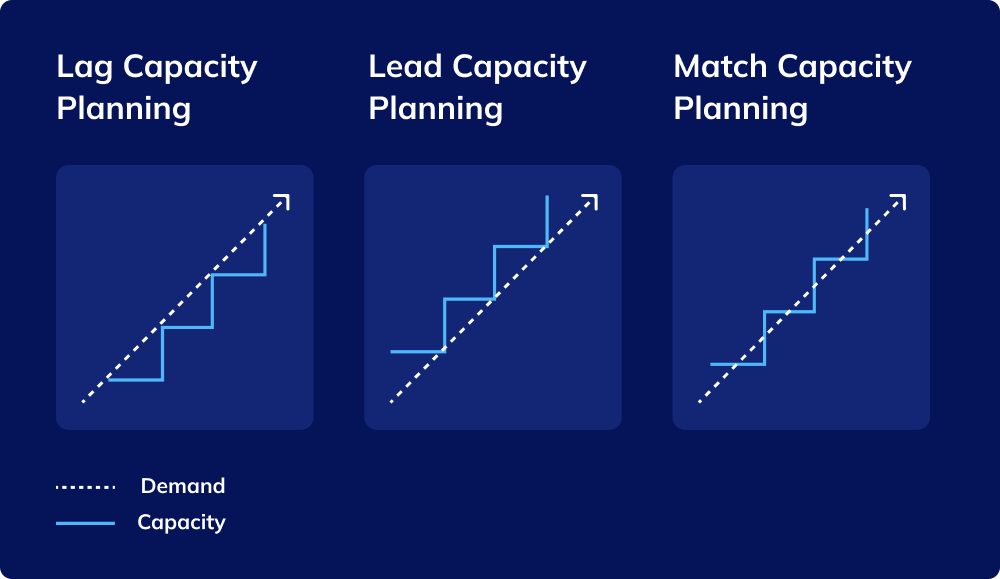

2. Lead, lag and match capacity planning

There are three main types of capacity planning: lead, lag and match.

- Lag capacity planning is where a business scales directly in response to demand – technically, always ‘catching-up’ with demand.

- Lead capacity planning is where a business pre-empts an increase in demand and scaling up, accordingly – effectively, always producing slightly ahead of demand.

- Match is a combination of lead and lag capacity planning, responding to demand while pre-empting further increases/decreases ahead.

Start-ups, smaller manufacturers or those with a very stable customer base often adopt a lag approach, as it enables stable, more organic growth and avoids the risk of producing excess stock.

For growing businesses, lead and match capacity planning can become a better approach, enabling manufacturers to respond to demand quickly and become more competitive with pricing and turnaround times.

3. Why is capacity planning important?

Capacity planning is key to running an efficient, optimised manufacturing process. At a time of rising costs, competition and skills shortages, capacity planning gives growing manufactures a vital competitive edge.

- Increasing revenue, not costs: Very simply, capacity planning helps you to bridge the gap between what you’re actually producing and your full potential. By identifying the gaps in your staff, machinery and product outputs, and optimising the performance of each, you can have full confidence that your cost of goods sold (COGS) is as low as possible.

- Customer confidence: If you don’t know exactly how much your team can produce, in any given timeframe, you can’t really be sure whether you can commit to customer orders – especially during busy periods or if an unusually large order comes in. (Before implementing Wiise, Terra Mater Floors would resort to guess work or ‘buffering’ stock to ensure big orders could be met). Capacity planning enables you to align sales and production team goals, ensuring that every order can be met.

- Better workforce management: Are your team constantly burnt out and working longer hours to meet customer orders? Concerned that your people are frequently under-utilised? Without knowing your current utilisation rates, it’s difficult to know whether hiring more staff will actually fix your capacity constraints – in some cases, over-hiring can worsen productivity! Capacity planning enables you to see your team’s actual productivity and identify inefficiencies.

4. Pros and cons of capacity planning

If you received a large order with a tight deadline, how certain would you be that you could deliver on time?

As your business grows, the ability to answer questions like this becomes critical and will make the difference between a production process that’s highly efficient and optimised – and one that is losing time, money (and customers).

The pros

Capacity planning enables manufacturers to:- Access the right resources, at the right time

- Anticipate and respond to demand

- Improve inventory management

- Avoid underutilisation

- Minimise excess stock

- Prevent staff burn-out

- Avoid missed deadlines

The cons

Capacity planning isn’t easy. Under or over-estimating trends is a trap that even Amazon has previously fallen into.

When sales spiked during COVID-19 pandemic, the Amazon reacted with a massive hiring spree, onboarding more than 175,000 new workers between March and June 2020. Just one year later, as pandemic measures eased, the online retailer admitted it had hired too many workers and had ‘overstaffed warehouses’. Since Q3 2022, Amazon has totaled 27,500 layoffs.

Post-pandemic, many businesses moved to a lead capacity planning (also known as ‘just in case’) approach – purposely producing and holding more inventory to overcome supply chain disruptions and delays. It’s estimated that Australian warehouse occupiers are holding up to 30% more inventory, compared to pre-pandemic levels.

Match planning requires highly accurate trend analysis and constantly adapting your workforce, processes and equipment, ensuring that you produce enough to meet demand without the risk of excess stock. Other challenges associated with match capacity planning include:

- Fluctuating demand:

Customer demand has become increasingly difficult to predict. While seasonality can often be predicted, competition, changes in customer preferences and global events are almost impossible to pre-empt – but robust contingency planning and highly accurate forecasting can help to predict the unpredictable. - Capacity restrictions:

Identifying a need for more capacity is one thing – delivering it is another. The time, cost and effort in finding more factory or warehouse space or sourcing new equipment, materials and labour takes time that can add to existing bottlenecks and delays. Improving end-to-end operations and processes can ensure that capacity planning becomes an important part of your business culture, rather than a one-off response. - Keeping COGS low

For manufacturers, every part of the production process can impact the cost of goods sold (COGS) – from raw materials to equipment energy use – which is why increasing capacity can become far more costly than for other industries. To scale while maintaining profitability, manufacturers must make informed, data-led decisions that will enable them to increase capacity without increasing overheads (and COGS).

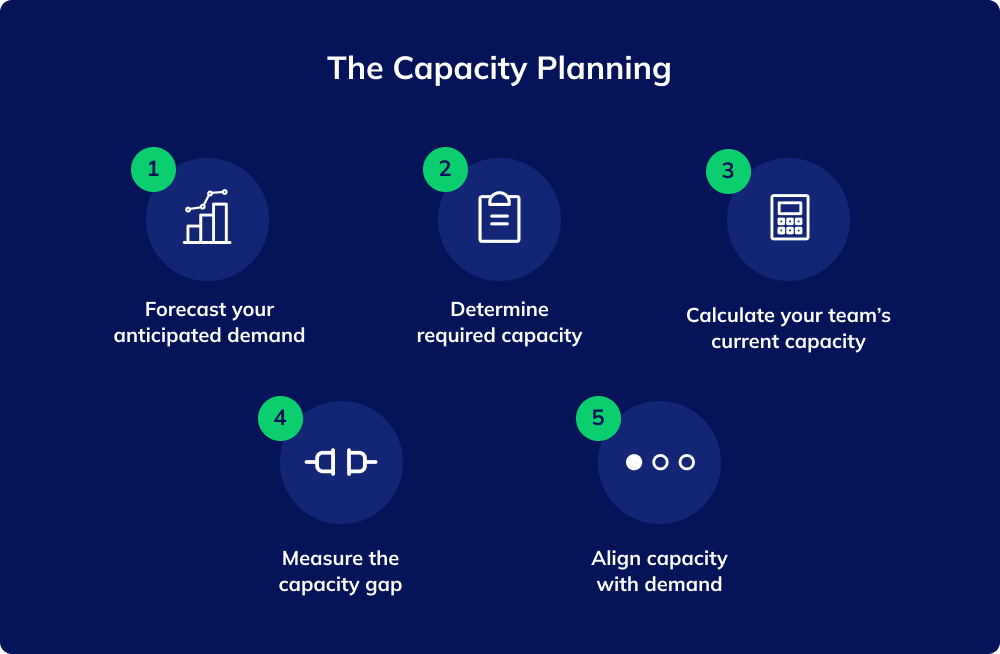

5. How capacity planning works

The capacity planning is simply the process of keeping track of demand and constantly analysing and adjusting your operations to keep up – but achieving this in a sustainable way, without risking profitability, can be a very difficult task.

Forecast demand

The first step is forecasting future demand from customers – by analysing historical purchase data, market trends, customer preferences, and other relevant factors to predict future customer buying behaviours.

Evaluate your capacity limit

This involves understanding the current utilisation and quantifying the maximum output limits that each of your existing resources (workforce, machinery, facilities and technology) can handle over a given period.

Knowing your current utilisation is, in itself, hugely useful – and can be a bit eye-opening if it’s significantly lower than expected. (As a benchmark, last year, the average capacity utilisation rate for US manufacturers was 77.1%).

Measure the gap

Compare the forecasted demand with your current capacity limit. The size of the gap will indicate just how much needs to change in order to meet demand.

Identify constraints

Work out what’s holding you back, causing bottlenecks and preventing you from meeting demand? Sometimes the answer might be simple, but will often relate to multiple issues, from space and equipment capacity to outdated processes.

Make adjustments

Time to remove the barriers to meeting demand. The most common ways to increase capacity include:

- Optimising resources – hiring staff, optimising production schedules or investing in new equipment.

- Adjusting Workflows – simplifying, automating and speeding up your internal processes can completely transform your capacity. (Terra Mater was able to double its orders, simply by automating its order processing).

- Technology Integration – modernising your operations with an advanced business tool, such as an Enterprise Resource Planning (ERP) system will enable to you automate and optimise various aspects of capacity planning, including inventory management, production scheduling, and resource allocation.

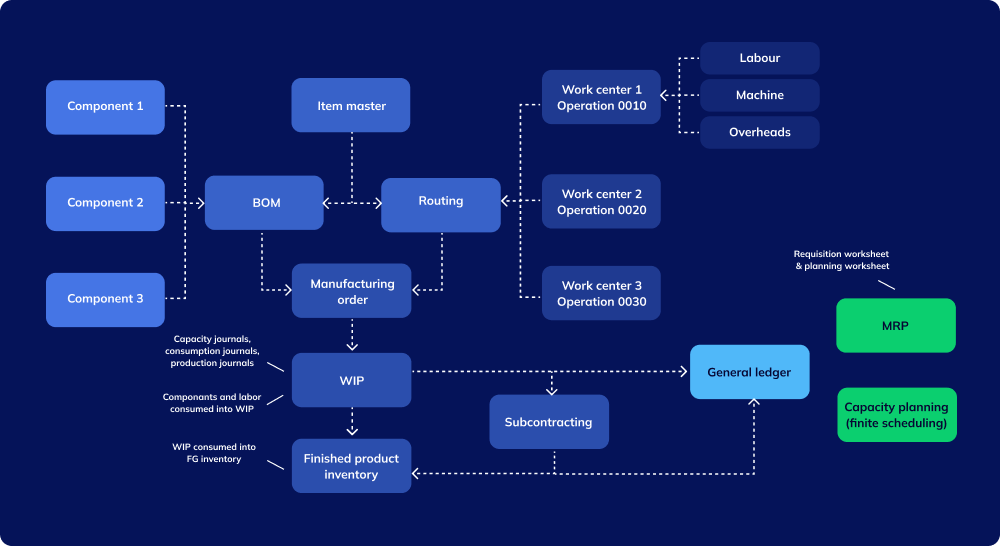

6. Advanced capacity planning with Wiise

Accurate capacity planning requires accurate, real-time data – and data analysis.

Wiise ERP offers the ultimate capacity planning functionality for manufacturers, with the ability to access and surface your operations data instantly, then analyse and predict demand using Microsoft Azure AI-powered reporting tools.

Wiise work and machine centres

Wiise enables manufacturers to see exactly how each part of their production lines are working at any given time, with the ability to see drilled down performance details at a group level, work centre level and individual machine centre level.

Capacity load reporting provides an instant view of up-to-the-minute timings and output quantities of specific workstations and machines (or people), alongside the quantities needed, available capacity and ‘expected efficiency’. The expected efficiency shows the additional capacity percentage – for example, a 10% expected efficiency would mean that your team has the potential to produce 10% more orders if needed.

Wiise production routing

Keeping track of on-going capacity is easy with Wiise. When a new production order is added, Wiise automatically creates a production ‘routing’, allocating that order to a specific work or machine centre, updating that work centre’s capacity in real-time.

Simply changing the start or end dates of a particular production order will instantly update the production routing and relevant work centre’s capacity, enabling manufacturing managers to see future and predicted capacity levels.

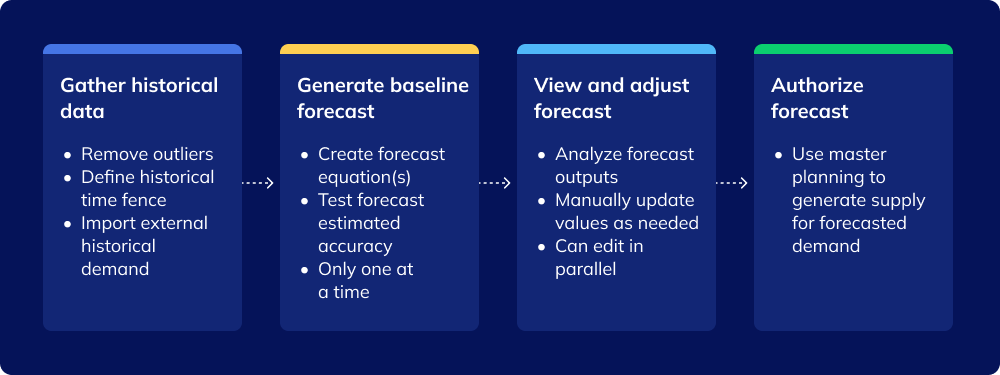

Wiise demand forecasting

Predicting future demand takes the guess work out of business decisions, minimising the need for ‘buffer inventory’ and helping to reduce fulfilment times.

Wiise demand forecasting provides useful worksheets where manufacturers can input historical sales, utilisation, production lead times, warehouse capacity and more to pre-empt bottlenecks and predict future demand.

Wiise sales and inventory forecast extension

The sales and inventory forecast extension uses Azure AI to predict future sales – enabling manufacturers to ramp up production ahead of time and always meet customer demand. Using sales history data, the Item Forecast pane charts your estimated sales and expected stock-outs, helping you to replenish inventory ahead of time.

7. Capacity planning and the bottom line

Good capacity planning can have a direct impact on manufacturing overheads, margins and the bottom line. Here's how two Australian businesses created real revenue saving with Wiise capacity planning tools:

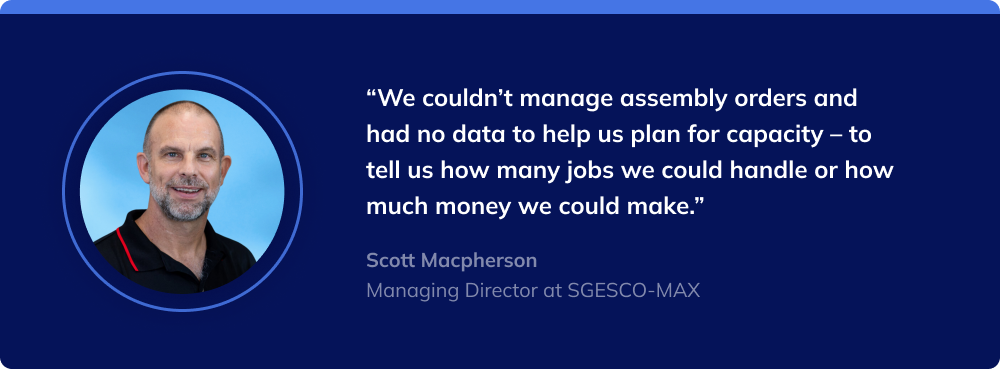

SCESCO-MAX’s story

SGESCO-MAX is the Australian leader in vehicle safety and monitoring solutions. When Scott Macpherson took the reins as Managing Director, in 2020, he saw an opportunity to pivot from services to manufacturing – but needed a business system that could provide the manufacturing capabilities needed.

Within 12 months of switching to Wiise, the business had begun to see real benefits and significant time-savings, including:

- Real-time capacity planning, enabling the company’s manufacturing team leader to see utilisation, forecast how many jobs can be taken on and their profitability to the business.

- 2,500 hours a year saved (equivalent of 1.5 of a team member) across the business.

- Creation of new customer kits – a result of being able to better manage inventory to create assemblies and sub-assemblies.

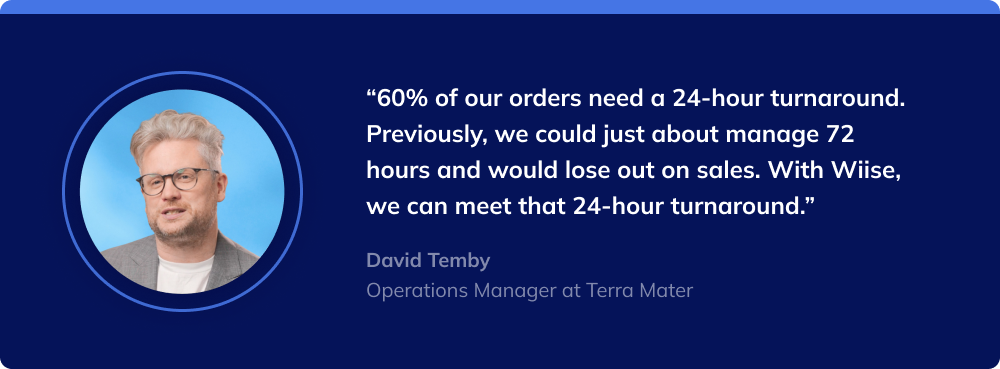

Terra Mater Floors’ story

In 6 years, Terra Mater Floors had grown from nothing to a 400+ customer business, with warehouses in Sydney, Melbourne and Brisbane. But, for a company that trades entirely in stock, its small business software left its staff struggling to manage inventory at the most basic level – unable to see which products were in stock or meet traceability requirements for its real timber products.

When Terra Mater’s Operations manager, David Temby, decided to switch to Wiise, his team was able to completely overhaul their internal processes – radically speeding up fulfilment times and increasing monthly orders:

- Automated order processing, cutting fulfilment times from 72 to 24 hours – resulting in an 82% growth in orders and 78% increase in shipments.

- Intelligent forecasting using Wiise capital management, cashflow worksheets and geo-budgeting – enabling the finance team to buy and sell stock more accurately, and eliminate wasted stock.

- Always-accurate inventory, enabling teams to see the exact location and quantities of future and current stock, minimising unsold stock or customer shortages.

8. Capacity planning with confidence

Minimised downtime, faster lead times and reduced overheads are just some of the ways in which accurate capacity planning can give manufacturers a competitive edge. The longer-term benefits of capacity planning – such as modernising your operations and having the confidence to deliver on bigger, last-minute orders – are key to building a more sustainable growing business.

Ready to cut your manufacturing overheads? Speak to one of our friendly team members to find out more about Wiise capacity planning today.

For further reading on modern manufacturing solutions, check out some of our recent blog posts:

Ready to learn more?

Book a demo call with one of our friendly team members.